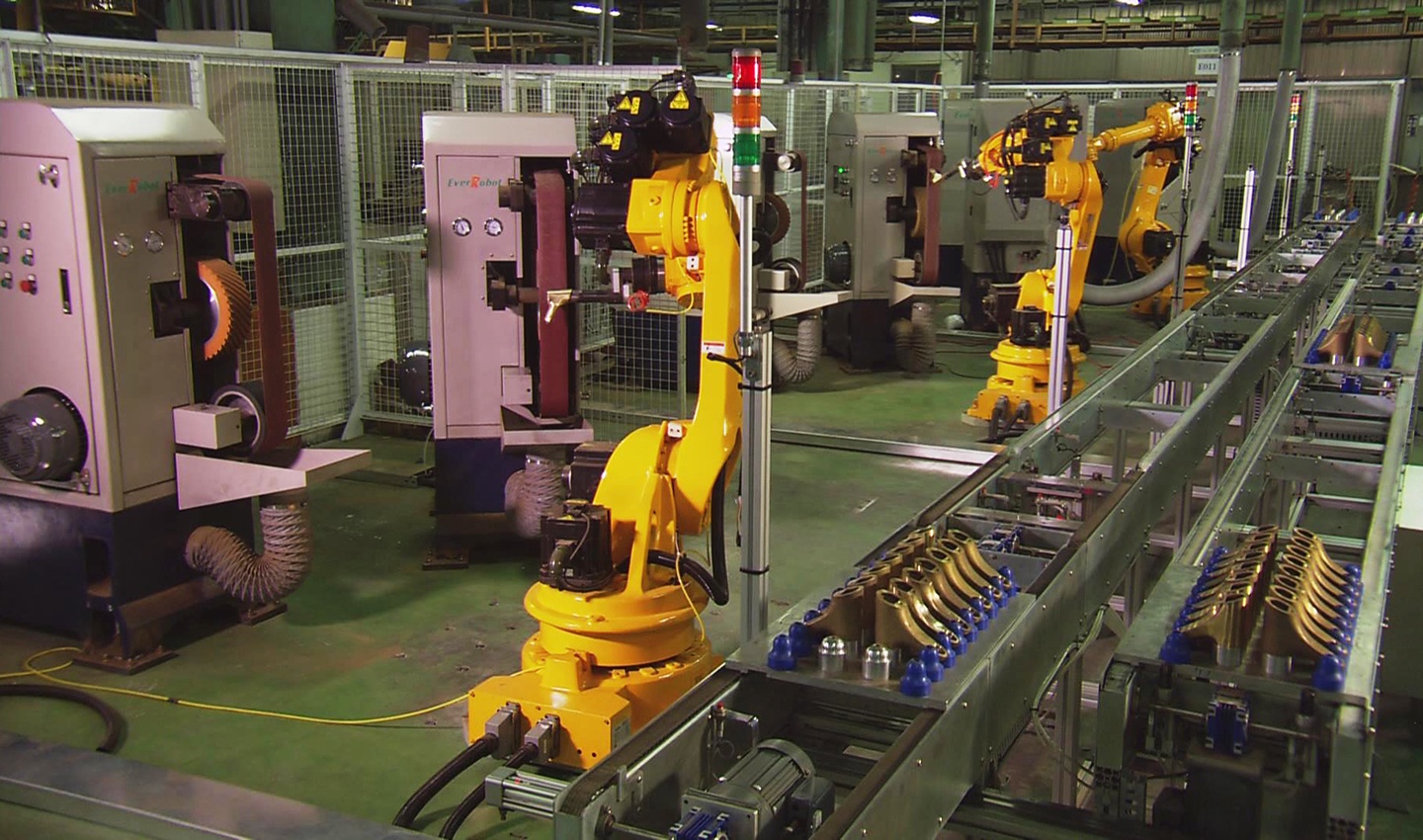

Polishing and polishing scheme for sanitary products

This program includes three RH60 industrial robots, belt polishing machines, special jaws, product conveyor lines, etc., to realize automatic grinding and polishing of sanitary products, replacing personnel in a high-pollution and high-dust environment, which can save 7 labor.

Description

Realize the replacement of production line models and reduce manual calibration points

After realizing the automation of the robot, the CPS (virtual-real integration) method is used, and offline programming software is used to generate the grinding path through computer simulation planning, which shortens the calibration time, and the grinding path can be completed in about one week, which saves time and quickly changes the line.

Maintain product consistency

After adopting robot automation, it is executed in strict accordance with the pre-planned path, with high repeat positioning accuracy, consistent quality and improved product quality.

Remote control

Through computer software to simulate the grinding road strength, interference and collision problems can be avoided.

Related products

Do you have any questions,

You can contact us by leaving a message or contact information.